If you’re facing recurring drain issues and dread the idea of your yard being torn up, pipe relining North Shore Services offers a smarter solution. This innovative method enables homeowners and property managers to repair damaged or blocked pipes without the necessity of disruptive excavation.

Relining technology has transformed the manner in which drainage issues are resolved, ensuring that they are resolved in a clean, quiet, and efficient manner, regardless of whether tree root invasions or collapsed pipelines cause them.

What Is Pipe Relining?

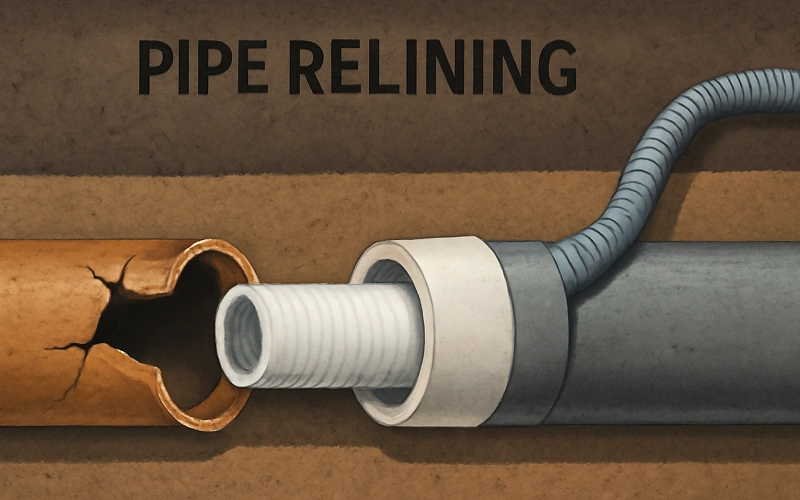

By constructing a new pipe inside an old one, pipe relining is a trenchless technique for fixing broken drain and sewer pipes. To do this, a liner soaked in resin is inserted into the damaged pipe, inflated, and allowed to cure. After hardening, it creates a seamless, long-lasting, and waterproof pipe that fully recovers functionality without requiring the old one to be dug up.

Why Traditional Pipe Replacement Falls Short

Traditional pipe repairs usually need excavation, which includes exposing the damaged region by excavating trenches, removing the broken pipe, and then installing a new one. In addition to being costly, this procedure is messy and time-consuming. It often leads to:

- Destroyed landscaping

- Broken driveways or walkways

- Disruption to residents or business operations

- High labor and equipment costs

In contrast, pipe relining is minimally invasive and far more cost-effective in the long term.

Benefits of Pipe Relining

1. No Need for Excavation

The most obvious benefit is that there’s no digging involved. Whether your pipes run beneath your home, garden, or paved surfaces, relining avoids the destruction of structures and landscapes.

2. Faster Completion Time

Since there’s no need to dig and replace pipes manually, the entire process takes significantly less time. Many jobs can be completed in just one day.

3. Long-lasting Results

The relined pipe is resistant to tree roots, corrosion, cracks, and wear. Most relining solutions come with a life expectancy of 50 years or more.

4. Cost Savings

Although the initial price may seem comparable to traditional methods, relining reduces indirect costs such as landscape repairs, property disruption, and downtime—making it a more economical choice in the long run.

5. Environmentally Friendly

Relining limits environmental disruption by reducing the need for excavation machinery, soil displacement, and waste generation.

Signs You Might Need Pipe Relining

Not every plumbing issue calls for relining, but if you experience any of the following symptoms, it’s time to get your pipes assessed:

- Frequent drain blockages

- Slow drainage

- Gurgling sounds from pipes

- Sewage smells indoors or outside

- Wet patches in the garden or lawn

A CCTV inspection is usually the first step a technician takes to diagnose the extent of pipe damage and determine if relining is the right solution.

Ideal Applications for Pipe Relining

Pipe relining is suitable for a variety of pipe materials, including clay, PVC, cast iron, and concrete. Common locations and scenarios include:

- Residential sewer systems

- Commercial drainage pipes

- Industrial wastewater lines

- Stormwater systems

- Pipes under driveways or buildings

North Shore-Specific Considerations

The North Shore area of Sydney is characterized by older residences, established trees, and leafy areas, all of which raise the possibility of pipe aging and tree root incursion. Additionally, excavation work is more difficult and disruptive in this location due to the mountainous terrain and dense residential layouts. Because of this, pipe relining is the best way to maintain plumbing systems with the least amount of negative effects on the environment and the property.

The Pipe Relining Process Step-by-Step

- Inspection – A drain camera is inserted to assess the pipe’s condition.

- Cleaning—High-pressure jetting is used to clear out blockages and debris.

- Lining Insertion—A liner soaked in epoxy resin is inserted and positioned.

- Curing—The liner is inflated and cured in place using hot water, steam, or UV light.

- Final Inspection—Another CCTV check ensures the job is done perfectly.